■Overview

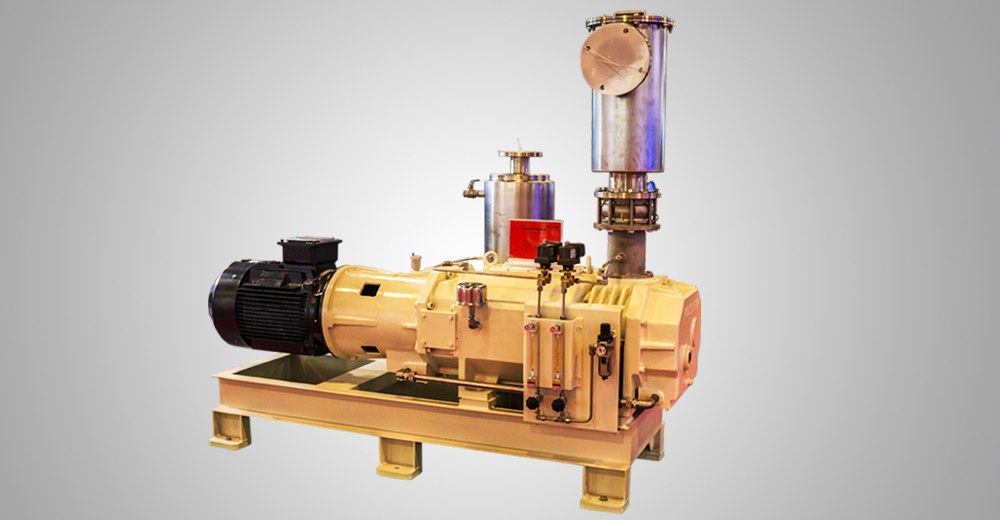

The best ultimate pressure and completely oil free

Unique screw rotor profile (patent) is used for VOLM ESDP series, which is with 30% power saving, low exhausting temperature and stable processing. This new product is suitable for vacuum processes in varied fields and maintains the best vacuum efficiency and durability.

ESDP series are oil free & water free, take variable compression operation and water vapor & liquid mixing process, which are very suitable for drying, solvent recovery, chemical, pharmaceutical, plastic and other vacuum processes.

■ Advantages and characteristics:

● Suction efficiency (risen by 15%).

● Exhaust efficiency is improved (2 variable grades, continuous variable frequency).

● Ultimate pressure: 1 * 10-2Torr.

● The exhaust temperature is reduced by 50%.

● Power consumption is reduced by 30%.

● Do not use oil or water, causing no oil or water pollution.

● Low power consumption, low noise, low vibration, good dynamic balance, no inertial force, high speed operation.

● Simple design structure, easy maintenance, low maintenance costs, no wearing parts, long life

● Wide range of applications, with high vacuum performance.

● Long service life, parts that gas is in contact with are coated with PTFE, nickel and Hastelloy.

● No mechanical seals, sealing parts are without pollution, will not cause frequent failure due to pollution.

● Use rare lubrication method for both ends, improve bearing durability.

■ Standard accessories:

Base and hood

Exhausting muffler and inlet air separator

Air intake

Check valve

Vacuum gauge

■ Optional accessories:

Suction filter

Exhaust condenser

Suction Type Gas - Liquid Separator

Flow switch and temperature switch

●The applications of ESDP dry screw pump:

The application of ESDP series in semiconductor synthesis and liquid crystal production mainly includes semiconductor plasma enhanced chemical vapor deposition (PECVD) and reflective ion etching (RIE) process, etching process in liquid crystal production and CVD process in TFT screen plasma production. This process requires a return of 0 to protect the work piece from contamination.

● In petrochemicals, it is mainly to suck condensable gases, or toxic gases, or corrosive gases, or gases containing micro-dust.

● In pharmaceutical industry, it is for the vacuum drying of drugs, for the recovery of drug intermediates and gas disinfectants, and to provide clean and sterile conditions for artificial organs.

● In chemicals, it is for vacuum distillation and solvent extraction recovery, such as extraction and recovery of acetone, polyols and other processes

● Industrial exhausting; Centralized vacuum processing system

● Mixing process of extruder and exhaust process of wood panel processing

● Deodorant process of mixed resins; To eliminate water pollution in the production of fatty acids and clear the stopper in the ejector

● For food industry, it is used for condensing of spices and flavors, food packaging and so on.

■Technical Data:| Model No. | Suction Volume | Ultimate Pressure | Motor Power | Speed | Inlet Diameter | Outlet Diameter | Liquid Flow | Noise | Weight |

| M³/h | Pa | KW | rpm | mm | mm | L/min | dB | Kg | |

| ESDP320 | 260 | 1.33 | 7.5 | 2900 | 65 | 50 | 10 | 80 | 320 |

| ESDP430 | 360 | 1.33 | 11 | 2900 | 65 | 50 | 12 | 80 | 380 |

| ESDP650 | 540 | 1.33 | 15 | 2900 | 80 | 65 | 12 | 80 | 580 |

| ESDP900 | 750 | 1.33 | 18.5 | 2900 | 100 | 65 | 20 | 80 | 680 |

| ESDP1500 | 1400 | 1.33 | 37 | 2900 | 125 | 80 | 30 | 82 | 950 |

For more detailed information, please contact us.